Single End Tenoner

SET-83-3M

Features:

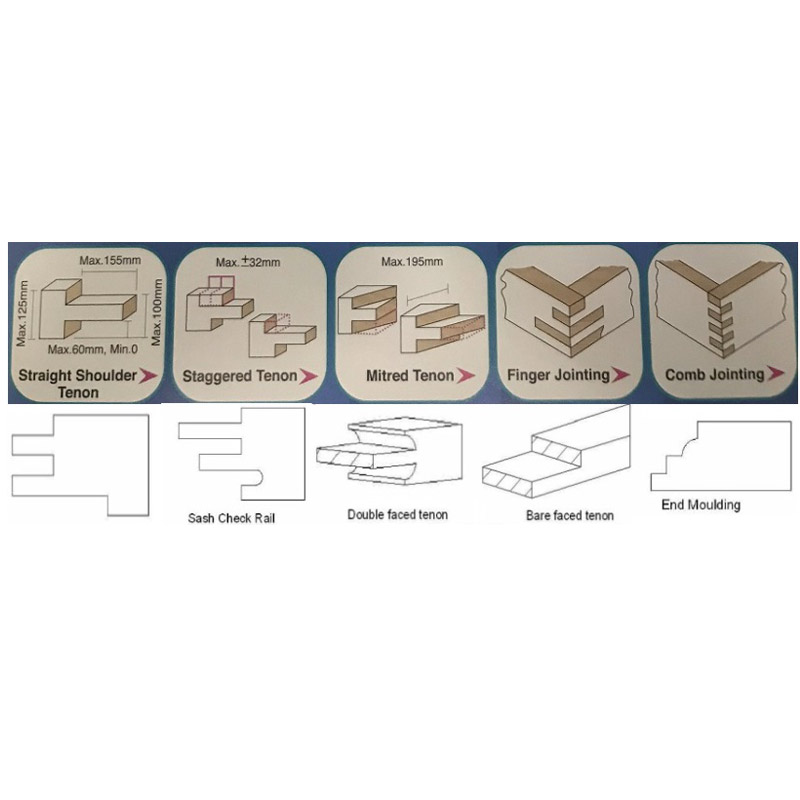

- It performs tenon, moulding functions.

- Three tenon cutters, cope spindles accepts general shaper cutter.

- Suited for cutting tenons, finger joints for windows or door frames and general joint-tenon.

- Hand, manually operated clamping and feeding of stock.

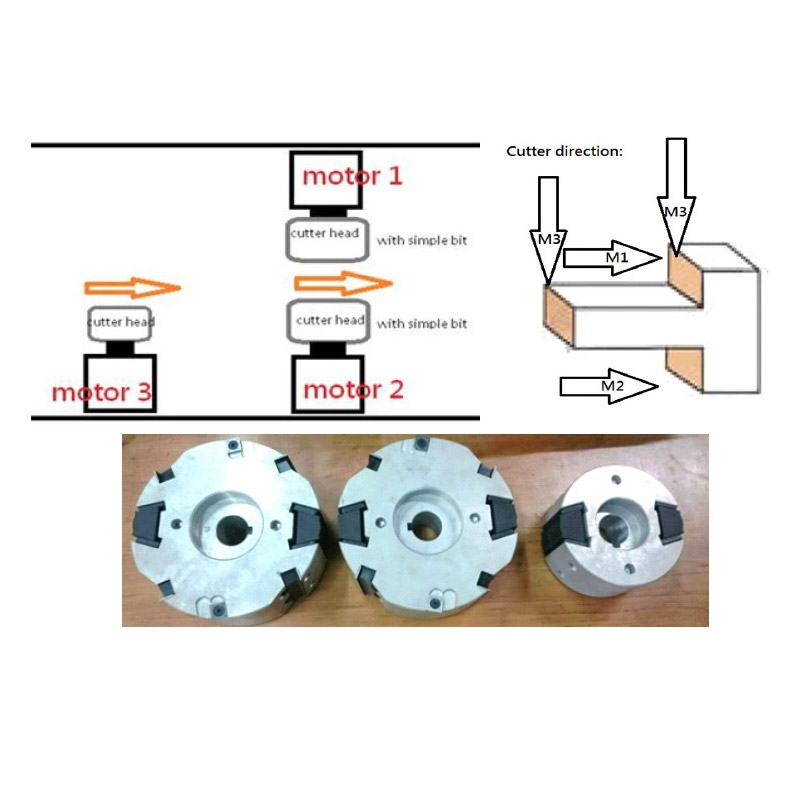

- Then two horizontal moulding, tenon spindles and one vertical coping spindle enables machine to perform edge tenon, moulding.

- Since each head is adjusted independently, a wide variety of tenons can be cut.

- At the end, the cope spindle provides 6000 RPM cutting, allowing to feature a spindle sharper function.

- All operations can be accomplished in a single pass of feeding; high efficiency is ensured.

- Powerful industrial motor for maximum cutting capacity

Specification:

- Table Size 31” W x 12” L

- CAPACITY

- Max. Length of Cut Un-limited

- Min. Length of Cut 5”

- Max. Width of Cut Pass Once 5", Pass Twice 8”

- Max. Tennor Height 5”

- Max. Tenoner Depth 6”

- HORIZONTAL COPING HEADS x 2 UNITS (M1 & M2)

- Cutter Head Dia. 6-3/4”

- Cutter Arbor Dia. 30 mm

- Cutter Head Length 2-3/8”

- Cutter Speed 4,000 RPM

- VERTICAL COPING HEAD (M3)

- Cutter Head Dia. 5”

- Cutter Arbor Dia. 30 mm

- Cutter Head Length 2-3/8”

- Cutter Speed 4,000 RPM

- TRAVERSE

- Saw Longitudinal Travel 3"

- Saw Vertical Travel 3"

- Carriage Cross Travel 20"

- MOTOR Saw & Tenoner Head 3 HP x 2, Cope Head 5 HP x 1

- Dust Hood Outlet Diameter 6” x 2

- Net Weight 1,020 LBS