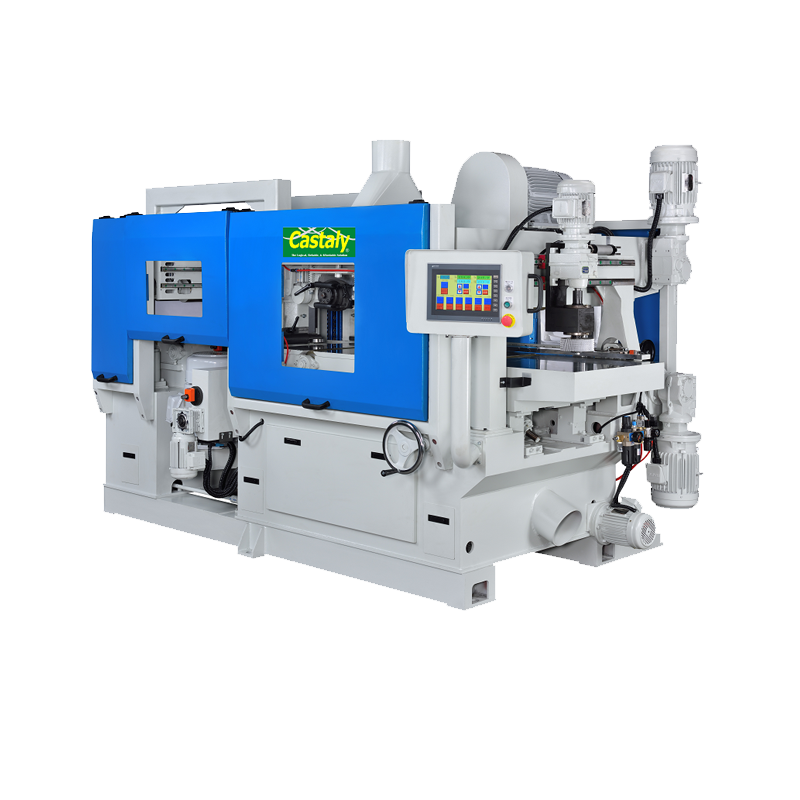

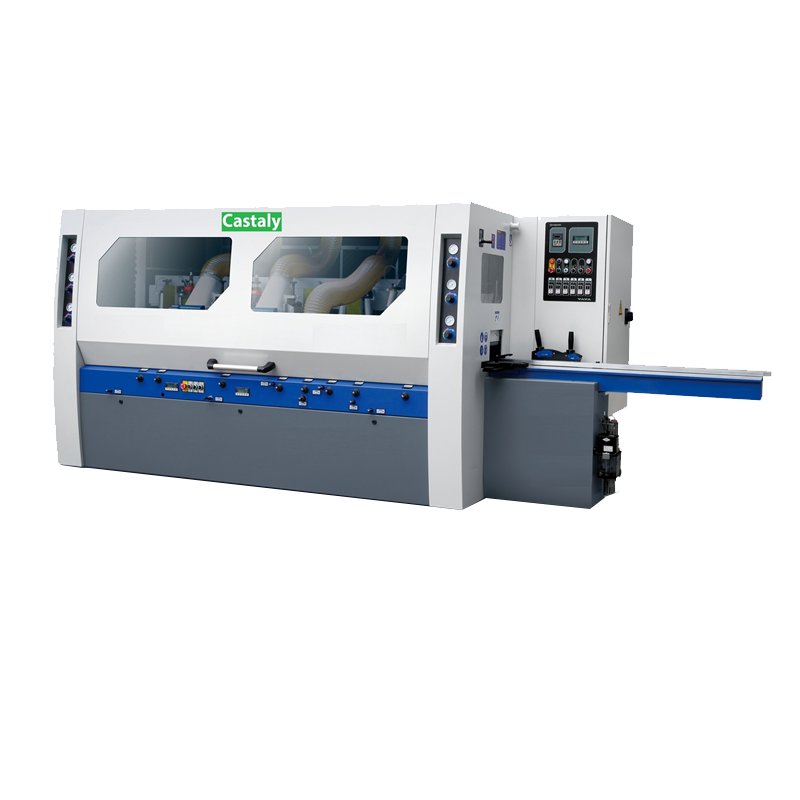

Features:

- Extremely compact construction great moulding / planning capacity extremely flexible performance affordable price.

- Automatic digital controller to automatic set thickness & width adjustment.

- Rigidly mounted alloy steel spindle with outboard bearing support: provides accurate vibration-free power transfer

- Spindle height adjustment by precision rack & pinion gears.

- The worktable surface was precision ground and then electric chrome-plated and polished to a smooth mirror finish. The durable wear resistance surface is easy to clean and maintain.

- A heavy-duty feed conveyor with metal spikes firmly holds stock securely to the worktable and feeds positively giving a smooth finish for rough or final planning.

- A variable speed invertor control for smooth adjustment of feed rate depending on the material hardness, depth of cut & width to provide the best finish surface and fast cutting performance.

- The floating power feed rollers are driven by geared transmission box linked with heavy-duty universal jointer, firmly holds stock securely to the worktable and feeds positively to provide a smooth, even feeding during rough or finish planning..

- The heavy-duty rigid cast iron frame supports the worktable and helps dampen vibration and ensures years of dependable service.

- Powerful industrial motor for maximum cutting capacity.

- All precision sealed long-life bearing for durability usage.

- A removable cutter heads are designed for convenient knife changing on the bottom cutter head.

- Changing the knife on the upper cutter head only requires removal of the upper dust chute

- The standard spiral insert heads design allows for fast, accurate insert changes and minimum down time.

- Setup time is minimized to set cutter head height using the auto material thickness device.

- All the cutter heads are precision balanced to provide consistently smooth chatter-free planning regardless of the feed rate or hardness of material being planned.

Specification:

| Specification | WP-4S2C-500 | WP-4S2C-650 |

| Working width | 2-3/4" ~ 19-5/8" | 2-3/4" ~ 25-1/2" |

| Working Thickness | 3/4" ~ 6" | 3/4" ~ 6" |

| Feed Speed (Variable) | 18 ~ 66 FPM | 18 ~ 66 FPM |

| Bottom Cutter Motor | 10 HP (Option 15 HP) | 15 HP (Option 20 HP) |

| Top Cutter Motor | 15 HP (Option 20 HP) | 20 HP (Option 25 HP) |

| Left Cutter Motor | 10 HP (Option 15 HP) | 15 HP (Option 20 HP) |

| Right Cutter Motor | 15 HP (Option 20 HP) | 20 HP (Option 25 HP) |

| Feed motor | 7.5 HP x 2 | 10 HP x 2 |

| Horizontal Cutter Dia. | 5" | 5" |

| Vertical Cutter Dia. | 5" ~ 6" | 5" ~ 6" |

| All 4 side Cutter's Shaft | 60 mm Dia. | 60 mm Dia. |

| Insert Cutter Knife Size | 15 x 15 x 2.5 mm | 15 x 15 x 2.5 mm |

| Dust Hood | 6" x 4 | 6" x 4 |

| Machine Size | 110" x 86" x 94" | 110" x 91" x 94" |

| Machine weight | 15,200 LBS | 18,600 LBS |

Related Products

-

20” x 5” Four Side Planer / Moulder

WP-20L-V4 $58,900.00 -

6" 4 Spindles Moulder

SM-154A $33,990.00 -

19-5/8” x 6” Four Side Planer / Moulder

WP-4S2C-500 $169,900.00 -

6" 6 Spindle Moulder

SM-156A $34,990.00 -

9" 5 Spindles Moulder

SM-235A $55,990.00 -

8" 5 Spindles Moulder

SM-205A $48,990.00 -

6" 5 Spindle Moulder

SM-155A $37,990.00 -

9" 6 Spindle Moulder

SM-236A $52,990.00